About tightening torque

The steering bosses manufactured by our company are designed to break if a large axial load is applied in order to reduce damage to the driver in the event of an accident. For this reason, the user’s manual and the notes accompanying the product also request that the tightening torque of 3kg-m be strictly observed.

When an average adult male uses a cross wrench to tighten a screw with both hands, he can easily apply about 6kg-m. If you try to tighten the wheel nuts to a certain extent, you will have to produce a torque of over 10 kg-m. (The recommended tightening torque for wheel nuts is 11 kg-m. (This is a natural mechanism considering that the recommended tightening torque for wheel nuts is around 11 kg-m. In rare cases, we have heard of cracks in the tapered portions, even though the torque is within the proper range (3kg-m). If grease or oil is adhered to the tapered portion, it can cause slippage and cracking even within the proper torque range.

I degreased the steering shaft with paper cleaner and tightened the center nut with a dial indicator torque wrench

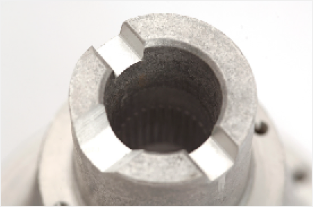

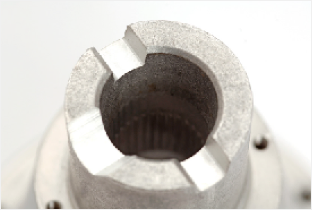

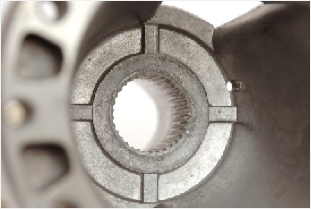

If there is grease or oil adhering to the tapered portion, it is likely to become black indentation* as shown here. Even after degreasing and cleaning, black indentations can be seen on items that have been tightened with excessive torque. The indentations can be mirror-like or faintly shiny, semi-mirror-like.

A faint indentation* remains on the inner surface of the taper.

Compared to the test at 3 kg-m, the indentation* is darker.

* Indentation: black circumferential marks on the inner surface of the taper

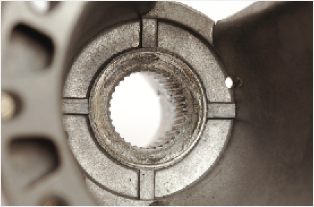

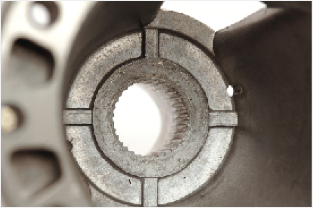

It is possible to judge the amount of torque to some extent from the bolt’s seat surface.

If there is grease or oil adhering to the tapered portion, it is likely to become black indentation* as shown here. Even after degreasing and cleaning, black indentations can be seen on items that have been tightened with excessive torque. The indentations can be mirror-like or faintly shiny, semi-mirror-like.

You can only see the faintest of friction marks around the boss’s seat surface.

There is almost no difference between 3 kg-m and 4 kg-m.

This reference is for the type that does not use a spring washer. Most of the non-Honda cars use the attached nut and spring washer. In that case, the center nut is loosened by shaving off a large portion of aluminum when loosening it, so it cannot be inferred from the friction marks.

Attention! The stock steering shafts are made of steel, but they are weak steel that has not been hardened. In our tests, when the tightening torque exceeds 6kg-m, the threaded and tapered parts of the steering shaft begin to stretch. As a result, the center nut (bolt) is tightened with excessive torque, and the steering shaft is stretched, so there is a possibility that the steering shaft will be damaged by pushing on the car body parts more than necessary, or it may lead to problems such as not being able to be installed correctly even if the steering wheel is returned to the stock steering wheel, so extreme caution is required.